17 Set WorkNC Dental at Implantology Seminar

WorkNC Dental, from Vero Software, played a significant role in creating an occlusal splint which was installed in a patient’s mouth, during a dental technology seminar.

The two-day seminar at the Sireix dental prosthetics centre, was for laboratories, dental prosthetists and surgeons, along with new technology partners focusing on “CAD/CAM – a useful and positive approach.”

The centre is at the Siriscan Machining Unit, in Agen, where Christophe and Vincent Sireix have invested in all-digital solutions and the development of digital impression scanning techniques. The SIRISCAN Machining Centre has been using WorkNC DENTAL CAD/CAM for over four years to program different NC machine tools, and the Implantalogy Module to machine implant prosthetics regardless of the type of connector that is required.

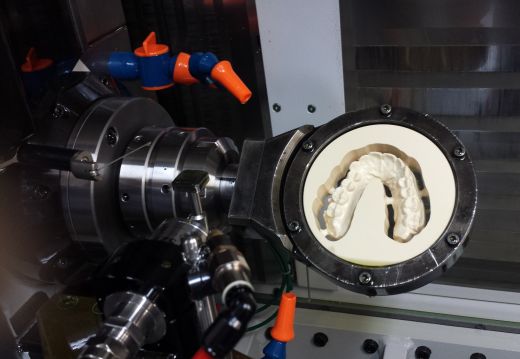

Machining the lower denture on a Willemin Macodel 408B

“WorkNC Dental has given us complete control of implant connector machining data, thanks to the Implantology Module, while remaining independent of the scanner, the dental CAD system and the machine tool,” explained Christophe Sireix during his presentation.

New technologies were addressed by the different partners during the course of the two days. Firstly, optical impression techniques were presented by Dr Arnaud Soenen, an expert in new dental technologies and digital dentistry, followed by a presentation of Imetric®, 3Shape®, Lava®, Dental Wings®, Sirona®, ZirkonZahn® scanners and, finally, the WorkNC Dental® CAD/CAM dental application, presented by Business Manager Laurent Journeau.

Based on real clinical examples, Doctor Arnaud Soenen, Christophe Sireix and Laurent Journeau demonstrated the benefits of digital technology in implantology to prosthetists and laboratories. The event focused on the clinical situation, the intraoral optical impression, and the CAD/CAM digital modelisation and conceptualisation.

Thanks to a patient requiring an occlusal splint attending the seminar, delegates gained a hands-on insight into the Trios® optical impression scan process, modelisation in Dental Wings®, data processing in WorkNC Dental® CAM and machining of the splint on a Willemin-Macodel® 308 B and the lower denture model on a 408 B, before the splint was fitted in the patient’s mouth.

Thierry Dusseau, from the DUSSEAU Laboratory, was impressed with the discussions and technical skills seen during the seminar: “A platform of highly competent speakers and technicians. Excellent interaction between dentists, prosthetists and machining specialists. A high level of information exchange and excellent organisation.”