01 Mag ZINC-O-FIX ANTICORROSION PROTECTION

Zinc-O-Fix Anticorrosion Protection

Although the Automotive’s field is in continuous development in order to reach the creation of state-of-the-art means of transport, using light alloys and specials materials to obtain high-performance vehicles, the corrosion’s problem still exists. This happens especially in the junctions elements, in the coupling between different metals, and specifically in the so-called “hot spot corrosion”. Hot spot corrosion are concentrated along:

- Car door hinges;

- The channelling located around the bot and bonnet;

- Welded or bolted body connections;

- Holes for bolts, fasteners and rivets;

- Lower borders terminals on the body –work.

The most common corrosion problems are:

- CREVICE CORROSION

- GALVANIC CORROSION

The crevice corrosion is due to a stagnation of substances, which originates corrosion (e.g. water, moisture). This phenomenon happens in correspondence to areas of coupling metals and especially between fastening elements (e.g. bolting of two elements), in presence of fissures.

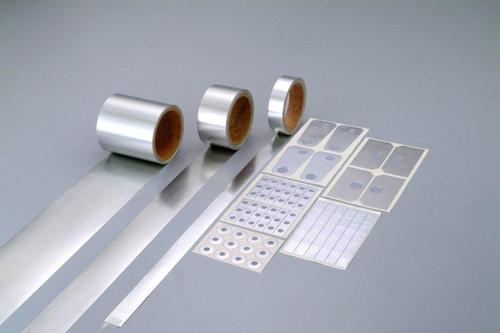

This specific corrosion problem can be avoided with preventive actions using as a protection Zinc-o-fix® product. This product has been used for many years in the production of vehicles and means of public transport, and for their maintenance. In the specific case, and in all corrosion cases due to the coupling of metals with fastening elements, the problem is solved introducing between the elements a shape created according to the client’s need

In the construction of means of transport, light alloys and steel are coupled, and in presence of electrolyte (moisture, water, etc.) a galvanic cell is activated starting the corrosion process.

When these two materials get in both electrical and electrolytic contact, a galvanic process begins. The electrolytic contact arises when a solution (usually rain-water) seeps between the two surfaces. This contact can even be caused by signs of dampness between the two surfaces or by a chemical non- homogeneity of one of the two surfaces because of the presence of oxides, dirt, etc.

Since the electrochemical potentials of steel and iron materials are more electropositive than light alloys, they can cause corrosion. This will not happen using Zinc-o-fix®, in fact it will stop any corrosion acting as a galvanic anode protecting both the surface of the light alloy and the steel.

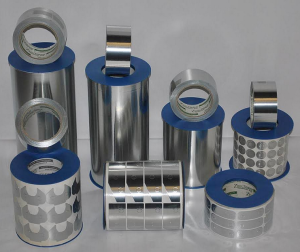

Zinc-o-fix® is a zinc-tape of high pureness (>99, 95% of the chemical mass of zinc) obtained from a specific alloy of own technical know-how, with a nominal thickness from 0,080 to 0, 45 mm. This tape is supplied with an electro-conductive adhesive, which can resist continuous operating temperature from -40 to +120° C. The conductive adhesive is a vital part of the Metalnastri’s zinc tape, because it allows also active protection against the corrosion (cathodic protection)

Advantage

- A particular cleaning of surfaces is not required

- No Primer required

- Guarantees a double protection compared to other treatments involving a remarkable saving in the time

- It is a definitive intervention

- Ensures a much longer life-span (from 1.4 to 2.0 times more) than that of hot-dip galvanizing or other zinc coatings of the same mean thickness.

- It can be applied in multiple layers, whenever an extra-thick coating is required

- Enables those areas where the hot-dip galvanizing layer has been damaged to be reconditioned.

- Many “onsite” applications

- Can be over painted

- No maintenance during the structure life

- Ideal for difficult access & dangerous structures

- Its application eliminates cost of maintenance in the course of the years

- Its application eliminates all risks deriving from the installation of continuous buiding site and scaffolding

- Economical on long life structure

- Environmentally Friendly